An extremely durable wood

Pine heartwood is naturally durable

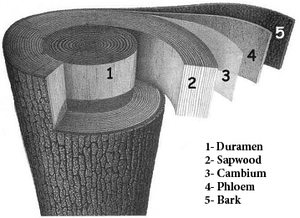

It is first important to understand that all species have what we call a duramen - the oldest part of the tree that no longer conducts the sap and serves only as a support - and a sapwood - the youngest, outer part of the tree.

As a general rule, the duramen (also known as perfect wood or heartwood), is differentiated, as with French pine trees that have a red duramen and a white sapwood.

Moreover, the duramen is naturally resistant to most wood-destroying fungi and sometimes to wood-eating insects.

This is also the case for French pine trees where the duramen is used for more than 10 years use class 3.1 and 3.2 (depending on the species); in other words, if the pine is located outside and exposed to weather but does not come into contact with the ground nor into prolonged contact with water.

"Natural durability" is the term used for the duramen.

See extract from the booklet FD P20-651 "Durabilité des ouvrages bois (Durability of Timber)"

Impregnable pine sapwood

Pine sapwood is very sensitive to wood-destroying fungi and mould of any kind. The "blue" fungus in particular, which gives the pine sapwood a blue/green colour, quickly develops on non-dried freshly sawn wood.

That's why it's important to dry pine timber as quickly as possible, or at least give it an anti-blue treatment.

Drying is the first stage in the preservation of timber.

Fortunately, pine sapwood can also be easily impregnated.

See extract from the EN 350-2 standard on the natural impregnability of the main European species

Photo Credit : RIBEYRE - SATB

For over a century, man has been inserting different types of fungicidal and insecticidal liquids into pine sapwood. The most common of these are copper salt solutions, which are still in use today.

To impregnate 100% of the sapwood, thereby completely reducing all risk of degradation, it is essential to pressurise the liquid used.

Outline

This pressurisation is done cold, at little energy expenditure, in a sealed cylindrical chamber called a vacuum autoclave.

Take note!

Do not confuse autoclave pressure treatment with pressureless soaking treatment.

Here is what the ARBUST association has to say (extract from their documents).

Impregnated pine is used in class 4

Pine products impregnated with copper salts are resistant to all known attacks on timber and can be used in class 4 (in line with EN335); in other words, in contact with the ground or with soft water, or placed horizontally in a water retaining position. A wooden terrace or pontoon are typical examples.

When timber has undergone preservation treatment to improve its durability, we use the term "improved durability".

The improved durability of the impregnated pine allows it to be classed as use class 4 for more than 10 years.

This is the only resinous wood solution that achieves such a level of fungi resistance in such unhealthy environments.

See the photo galleries showing the uses of class 4 pine

- Terraces

- Structures in a marine environment or on the river

- Structures in the forest

- Amusement parks

- Etc.

Arguments in favour of impregnated wood in an autoclave

Today, pressure impregnation of pine is by far the most widely used solution for wood used in exposed locations. This solution has stood the test of time for decades.

Some manufacturers even offer 25 year guarantees on "grade 4 pine".

This process has several advantages:

- It is standardised. This is the only wood preservation process included in the standards, and the only process to have its results (the product penetration depth and the quantity of the product in the wood) defined in legislation.

- It is assessed and controlled; certification can be obtained, with the CTB B+ quality mark issued by the FCBA

- It is energy-saving. The process is undertaken at room temperature, and only one pump is used for vacuuming and increasing pressure.

- It is quick. One pine impregnation cycle lasts two hours maximum.

- It is productive. In France there are less than 50 vacuum autoclaves, each capable of impregnating around 10,000 m³ of wood per year.

- It is reliable. This process has been used throughout the world for over 50 years without any major problems.

- It is accessible. Impregnated pine is the most economical solution for guaranteeing the wood maintains use class 4 status for 10 years or more.

- It respects the wood. The impregnation process does not alter the mechanical properties of the wood (in line with NF EN 15228 standard)

The appearance of pine after impregnation in an autoclave

As for the appearance of impregnated pine, it normally takes on a green, greyish colour.

For several years brown coloured impregnated pine has also been available.

Some manufacturers also offer grey impregnated pine but this currently cannot be classed as use class 4.

Irrespective of its original colour, the colour of impregnated pine remains more or less the same over time, and the natural greying of the wood is delayed.

Take note!

Once impregnated, pine, fir and spruce are often confused because they are close in colour. However these species are very different when it comes to durability. Fir and spruce are much less permeable than pine and therefore have a lower improved durability. Impregnated fir and spruce can be classed class 4 but their longevity is much less certain. They are mainly used for temporary structures.

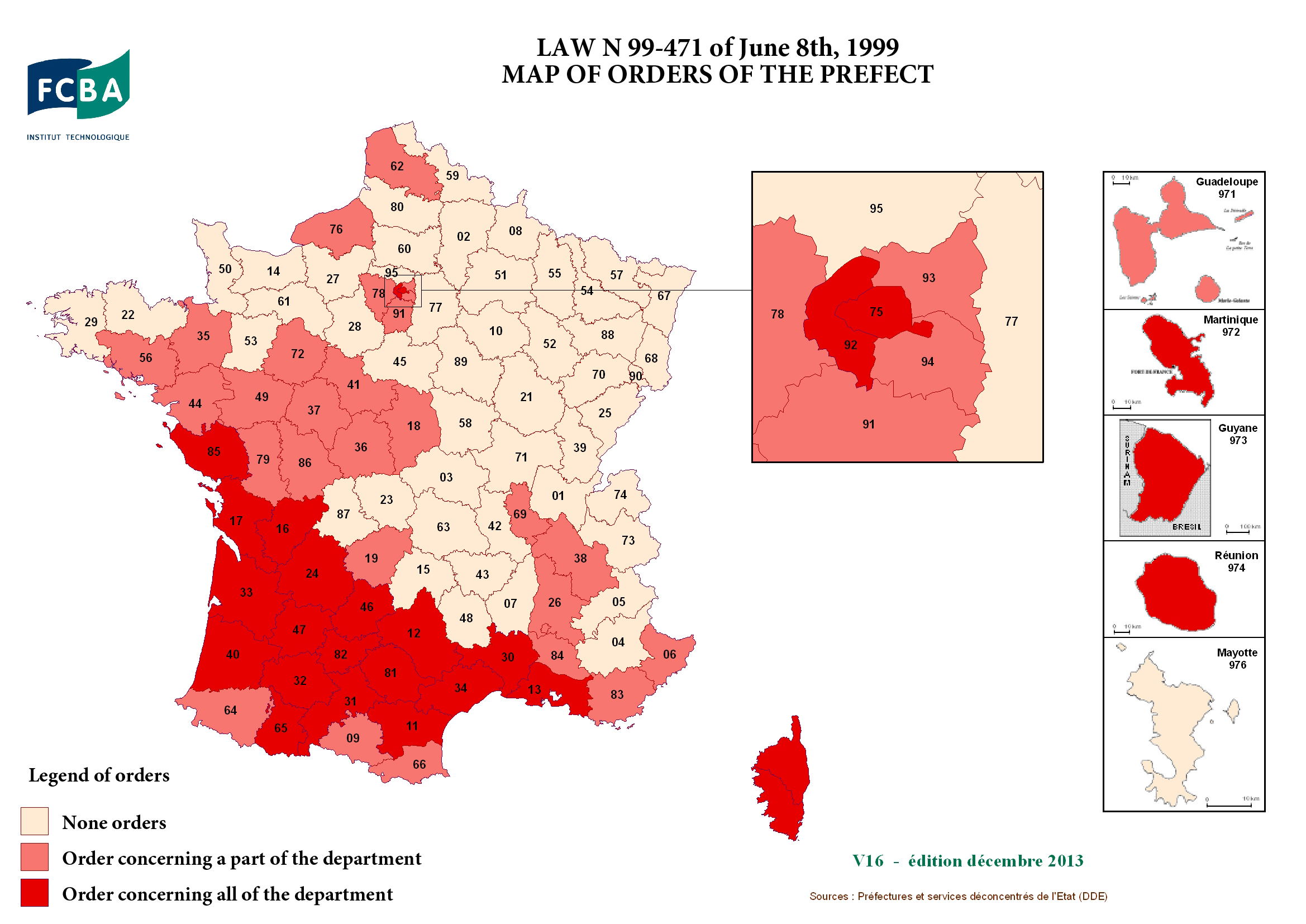

Class 4 in standards and regulations

The termite is a scourge that has resulted in numerous regulatory precautions including articles L.112-17, L.133-1 to L.133-6, L.271-4, R.112-2 to R. 112-4, R.133-1 to R.133-8 and R.271-1 to R.271-5 of the construction and housing code.

However, pressure impregnation is one of the best methods for making impregnable woods termite resistant. Impregnated pine is therefore ideal for use in wood structures throughout the regions of France colonised by termites (a good third of the South-West - as shown on the map of "termite-infested" regions declared by prefectoral decrees) and in the French overseas territories.

In fact, all wooden structures in these regions that cannot be visually monitored must be treated with anti-termite solution, which often include timber framework, terrace decking and floor joists.

According to NF DTU 31.2 "Timber frame construction", the the bottom plate supporting the walls is often classed as use class 3b or 4. Therefore placing your timber wall framework on "use class 4" impregnated pine bottom plates is a security guarantee and ensures the structure conforms to all professional regulations.

See the "Timber framework" product page

According to NF DTU 51.4 "Timber decking", the ledger strips supporting the timber/ wood composite decking are considered as use class 4. Although certain more exotic woods are suitable for this purpose, impregnated wood is by far the most economic and widely available solution. Moreover, pine offers several advantages when installing a terrace because it has a low density and is therefore easy to shape. Screwing deck boards into a pine ledger strip is therefore very simple and doesn't even require pre-drilling.

According to the same NF DTU 51.4, deck boards themselves in their current design (rectangular cut) and present use are considered use class 4. This makes impregnated pine the ideal solution for terraces, as it is widely available, has a great price/quality ratio and is durable.

According to NF DTU 41.2 "Outdoor timber overlay" in its latest version published in 2014 some cladding is considered use class 4. This is the case with rectangular boards and battens in a clerestory without a slope for water flow, and with joining contours where the pattern at the join would cause waterlogging. In these cases, the secondary framework of the cladding is also considered use class 4 due to the humidity stagnation risk. For security reasons, it is advisable to use impregnated timber framework, irrespective of the cladding type, which will guarantee a long-lasting structure and ensure the cladding holds up well over time. As with wall framework, it is also difficult to examine the state of cladding framework. Using impregnated pine is therefore an extra assurance at a low cost.

Moreover, some cladding may obviously be exposed to permanent humidity, either because it is positioned in shadow, next to water, or in a damp area, or because it has a large diameter. Of course, it is rarely a true use class 4 but for security reasons this type of "at-risk" cladding should be made of impregnated pine to put the project owner's mind at rest.

Have you ever done the maths?

Using impregnated pine for the walls and gutters of a timber frame house will cost around £450 more for a 150 m² house.

That's pretty good value for guaranteeing the structure against any risk of accidental damage.